Diagram of SPIRAL2 linear accelerator. The beams generated by the heavy-ion and proton/deuteron sources are injected in the RFQ. The medium-energy beam transport (MEBT) line shapes the beams, which are then injected and accelerated in the type A then type B cryomodules to reach 40 MeV.

Since 2004, SACM has been a major actor in the SPIRAL2 project. It played a leading role during the detailed design phase, and installed and finalized the light-ion injector at Saclay in 2012. In parallel, the department designed and developed the RadioFrequency Quadrupole (RFQ) and the low-beta cryomodules of the accelerator. All of these systems have now been delivered and installed in the SPIRAL2 tunnel at the GANIL laboratory. The proton and deuteron injector, comprising the source and the low-energy beam transport lines, was thus commissioned at GANIL and injected its first beams in the RFQ at nominal current. The RFQ is now in the qualification phase.

At the end of the integration period, beams will be injected in the next section of the accelerator, consisting of two families of quarter-wave superconducting cavities. Cooling the 19 cryomodules (A and B) and commissioning of the SPIRAL2 accelerator and the experiment rooms (SPIRAL2 Phase 1) are scheduled for 2017.

THE RADIOFREQUENCY QUADRUPOLE

The radiofrequency quadrupole provides beam bunching and pre-acceleration functions essential for effective energy transfer in the upper stages, while ensuring particle confinement. IRFU was in charge of design, construction, installation and commissioning of the SPIRAL2 RFQ at the GANIL laboratory. The RFQ consists of five copper sections, each 1 meter long, weighing 1.6 tonne, manufactured separately to an accuracy of ± 65 μm, then assembled to an alignment accuracy of ± 10 μm. Any irreducible geometric faults are compensated for by adjusting the 40 pistons inside the cavity, so as to tune frequency appropriately and achieve the voltage curve required for beam dynamics. Continuous 240-kW RF power is required for operation. Thermalization of the cavity is ensured by a complex water circulation system at controlled temperature. The accelerator field is controlled by a Low Level RF systems designed and supplied by IRFU. This system is also installed on all the accelerator cavities. The cavity was ramped up to full field for the first time on November 15, 2015, preparing the way for acceleration of the first proton beam to its nominal energy of 0.75 MeV (for a voltage of 50 kV) on December 3, 2015. In months to come, RFQ qualification tests will continue until the RFQ reaches the nominal voltage of 113 kV required to accelerate increasingly heavy ions.

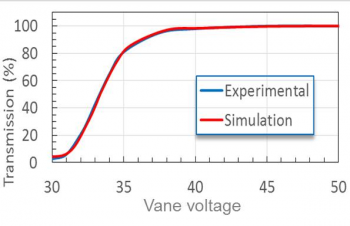

Beam transmission curve as a function of voltage applied to the RFQ vanes. The observed match confirms the geometric design of the RFQ vanes as well as the complex tuning process used by IRFU teams to adjust voltage. It also provides further experimental proof of the accuracy and predictive capability of simulation codes developed at SACM.

LOW-BETA CRYOMODULES

The SPIRAL2 superconducting linear accelerator includes two types of cryomodules, featuring cavities with geometry optimized for accelerating particles to 7% the speed of light (12 type-A cryomodules, each comprising a low-beta cavity: β = 0.07, built by IRFU) and 12% the speed of light (seven type-B cryomodules, each comprising two high-beta cavities: β = 0.12, built by IPNO). Each type-A cryomodule contains a single cavity, manufactured from solid niobium and fitted with a power coupler capable of injecting 10 kW of continuous maximum radiofrequency (RF) power. These couplers are supplied by the Subatomic Physics and Cosmology Laboratory (LPSC) in Grenoble. The cryogenic system, associated with a thermal screen and multi-layer superinsulation, cools the cavity to 4 K to establish its superconducting properties. A mechanical system is used to adjust the cavity frequency by deforming the cavity walls at extremely high resolution (to within a few nanometers) over a wide amplitude (2 millimeters).

The last four type-A cryomodules were assembled in the new clean room of building 124 East at Saclay between June 2014 and June 2015. The 12 low-beta cavities meet the accelerating field specifications (greater than 6.5 mV/m) and the Q0 quality factor (greater than 3.5 x 108). The cryomodule thermal losses are below the 21.5 W required by the GANIL laboratory. The cavity frequency variations, controlled by the mechanical tuning system, are consistent with predictions, and the hysteresis and linearity of the system are excellent.

After IRFU and GANIL installed the first cryomodule on the linac, working together to transfer the know-how, GANIL installed the other 11 type-A cryomodules alone, making connections to the cryogenic valve boxes, and to the hot sections, including the magnets used to correct the path under laminar flow. Tests conducted under pressure showed leakage under hot conditions of approximately 10-7 mbar·L/s on the 4 K helium line of a cryomodule at a pressure of 1.5 bar. The leak was repaired after the necessary investigations. Installation and connection of the last type-A cryomodule are scheduled for May 2016.

THE S3 SPECTROMETER

The Super Separator Spectrometer (S3) will benefit from the high-intensity, heavy-ion stable beams delivered by GANIL’s SPIRAL2 superconducting linear accelerator. S3 will achieve high-mass transmission and resolution using high-acceptance superconducting magnets, including sextupole and octupole correctors. S3 includes a rotating target designed to withstand the high-intensity beams delivered by the linac, a two-stage optical structure featuring a momentum achromat, followed by a mass spectrometer that achieves a high selectivity of the nuclei. The first stage suppresses most of the background nuclei. An open-multipole triplet based on conventional technology serves to evacuate and stop the primary beam. SACM and SIS are contributing to the design, construction and production management of the open quadrupole triplet that includes the sextupole correctors, the vacuum chamber and the beam dumps, subject to high-power energy deposition. Magnetic measurements performed on each multipole revealed excellent agreement with the results of simulations conducted at SACM during the design phase. Experiments were performed on the BETSI test bench using a 17-mA proton beam at 40 kV to bombard a prototype beam dump provided at the exit of the triplet and then observe the temperature rise and the impact on the material. This measurement campaign helped validate the beam dump design before launching the manufacturing process. The vacuum chamber was built within the very tight tolerance required for mounting inside the triplet, scheduled for acceptance at GANIL in the first quarter of 2016. S3 is scheduled for commissioning in 2018, along with the first beams from SPIRAL2.

• Accelerator physics and technology › High-Intensity sources and injectors