The 11.7 T whole body magnet and RF antenna, developed as part of the ISEULT project, will be installed at NeuroSpin in 2017. Thanks to these two core parts, the ISEULT MRI system will help push back the boundaries on brain research.

The magnet is being manufactured by GE (formerly Alstom) in Belfort and the first 7 T antenna network, consisting of eight channels was built and tested at NeuroSpin. A new 12-channel antenna is currently being tested. The 11.7 T antenna for the ISEULT project has already been built to the same design.

WHAT IS THE ISEULT PROJECT?

Magnetic resonance imaging (MRI) is a diagnosis and research tool used in the neurosciences. In 2017, a 11.75-tesla superconducting whole-body magnet with a 90 cm diameter bore will be delivered to the NeuroSpin center.

This magnet will be used for magnetic imaging in conjunction with new pharmaceutical contrasting agents to advance knowledge of brain functions, thanks to a resolution ten times higher than that obtained using the most powerful whole-body MRI system currently available at Neurospin, The imager will be used in both fundamental research in cognitive sciences and in the diagnosis of neurodegenerative diseases.

The ISEULT project is part of a wider French-German collaboration involving the leading manufacturers in the industry including

THE CHALLENGES OF THE ISEULT PROJECT

The ISEULT magnet design includes a number of key characteristics and different technical solutions compared to commercial MRI magnets. Five main technological challenges had to be addressed:

? 1. High-intensity magnetic field (intensity of 11.75 T, more than 200,000 times the Earth’s magnetic field).

? 2. Large usable volume (imaging of the whole body and more especially the brain, a volume of several liters compared with the other imaging system already installed at the NeuroSpin site, which generates a field of 17 T but in a useful area of only a few cubic centimeters).

? 3. Temporal stability (obtaining a magnetic field that does not vary by more than one billionth of a tesla over ten minutes).

? 4. A magnetic field that is homogeneous to within 5x10-7 T throughout the volume of interest corresponding a sphere of 22 cm in diameter.

? 5. Confinement of the magnetic field within the experiment room using an active shielding obtained thanks to two additional coils.

The coil consists of more than 180 km of niobium-titanium superconducting wire wound in double pancake coils and carrying a current of 1,483 A. These superconducting coils are maintained at very low temperatures (1.8 K or -271 °C) using a bath of 5,000 liters of superfluid helium, and they are separated from the exterior by a series of insulating vessels.

A development program including several prototypes and dedicated test facilities were required in order to solve these problems and to find acceptable technical solutions

YEARS OF R&D

Eight dedicated prototypes and test facilities were developped and, tested between 2008 and 2012, to validate technical solutions, to demonstrate assembly procedures, as well as to check the conductor capability to operate under nominal magnetic field and associated mechanical forces.

This includes the R1 prototype, made from an assembly of six double pancake coils, with an inner radius of 185 mm and an outer radius of 240 mm. It was designed to generate a 3.5 T magnetic field at 5,000 A. Each double pancake coil consists of 11 turns of the final ISEULT conductor and it uses the same components and manufacturing procedures as the final magnet. The R1 prototype was aimed at applying a higher level of mechanical stress than that applied by the ISEULT magnet, measuring the critical current of the conductor at 4.2 K for a mechanical stress level equivalent to the 170 MPa of ISEULT. The objective was also to gain experience in winding the ISEULT conductor and in making electrical junctions. This prototype successfully reached the peak conductor stress of 225 MPa, well above the nominal stress expected on ISEULT. The H0 prototype is a one-tonne solenoid made of a stack of 24 double pancake coils with a 480 mm inner radius that produced. a 1.5 T magnetic field. The main goal was to validate the innovative winding technique invented for ISEULT and to show that it could reach the specified field homogeneity. This prototype also validated the field stabilization mechanism specifically developped for ISEULT in collaboration with CNRS. These excellent results concluded the final qualification phase of the components and manufacturing procedures for the ISEULT magnet. Fabrication by Alstom started in February 2012, using the technical solution prepared by CEA and the manufacturing techniques defined at the end this R&D phase,

View showing insertion of the shielding coil support structure around the main magnet made of 170 double pancake coils.

AN INDUSTRIAL ADVENTURE

Detailed design of the magnet began in 2009, leading to more than 3,000 drawings. Once the drawings for a particular unit were completed, production was outsourced to specialized manufacturers. These included: Luvata Waterbury Inc. (US) for the superconductors, Zanon (IT) for the cryogenic and vacuum vessels, Roechling (FR) for the 1,360 spacer plates, machined within tolerances of 0.05 mm, Cryodiffusion (FR) for the satellite, heat pipe and cryogenic line, Air Liquide (FR) for the liquefier, and Jemma (SP) for the stabilized power supply.

After completion, the magnet parts were delivered to Alstom, the project partner in charge of winding and integration of the magnet. External parts, cryogenics and measurement, control and power electronics were delivered to the NeuroSpin site.

CONSTRUCTION OF THE MAGNET AT ALSTOM/BELFORT

Construction began with winding the 170 double pancake coils with a 2-m outer diameter. A special computer-controlled winding machine was developed to achieve the extremely tight dimensional tolerances required, which are equivalent to a hair's thickness. At the same time, the two active shielding coils, weighing 10 tonnes each, were built on their mandrel. In 2014, integration of the shielding coils and double pancake coils into their cold mechanical structure began.

Stacking the 170 double pancake coils was laser-controlled to ensure an overall alignment above one millimeter over four meters in height.

In 2015, the cold mass was finalized with the shielding coil support structure being inserted around the central stack.

In 2016, the helium vessel was closed and turned over to the horizontal position. The final magnet fabrication will be finished in early 2017 with the integration of the thermal shield and vacuum vessel.

The 132-tonne magnet will then be transported to NeuroSpin from Belfort to Saclay This oversize load will be carried via Strasbourg, up the Rhine to Rotterdam along the Channel and on to the port of Corbeil, before its final delivery to NeuroSpin.

PREPARING THE EQUIPMENT AT NEUROSPIN

The cryogenic system was designed to continuously cool down the magnet (with a colling capability of 21 W @ 1.8 K and 610 W @ 55 K), 24 hours a day and 365 days a year. It has already been installed in the NeuroSpin basement. It comprises a liquefier from Air Liquide, delivered in 2010, and the cryogenic satellite. This is an essential component to connect the magnet to the liquefier, power supplies. It also includes a 1.8 K LP/HP heat exchanger that ensures operation with a pressurized superfluid bath.

The DC power system includes two power converters. The first one powers the magnet up to the nominal current of 1,483 A at 40 V, while the second supplies one magnet with a constant power supply at the nominal current in stabilized mode. These two power supplies were delivered, installed and commissioned at NeuroSpin in 2015. The entire electrical power system (40 freewheel diodes, one-tonne external dump resistor, power contactors, nine stabilized 40 A power supplies for the active field correction channels, 48 V battery network) was delivered and connected in 2016.

The magnet control system that manages all the ancillary (power supplies, liquefier, cryogenic valves and temperature levels), was developed by CEA using high-reliability controllers. It comprises more than 300 sensors and actuators.

The data acquisition system, which collects both cryogenic and electrical data, was also specially designed for CEA and commissioned in 2016.

The quench detection system, based on measurement of the magnet’s voltages, required specific development to optimize system reliability.

THE FUTURE

The commissioning phase of the magnet and of the ancillary equipment will start at NeuroSpin in 2017. The first images using the RF antennas, developed in a joint laboratory between SACM and Neurospin, should be produced one year after the start of commissioning.

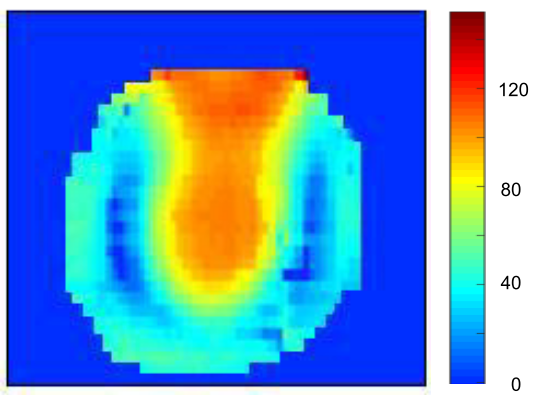

Angular illumination of nuclear spin flipping, obtained in the area equivalent to the top of a head (right part) using the disk resonator.

DEVELOPMENT OF MRI ANTENNAS

Since 2008, the development of MRI antennas for the very high magnetic fields of the ISEULT project has led to many innovations validated using a 7-tesla scanner already in operation at the NeuroSpin center. These innovations, protected by patents, relate to:

? Antenna technology, specifically the configuration of the transmitter and receiver coils elements, RS signal routing and coil decoupling.

? Parallel transmission imaging methods (kT-points, universal pulses).

This enables uniform excitation of hydrogen nuclei spin with an antenna array that compensates for the inhomogeneity of the magnetic field associated with the electromagnetic wave. This inhomogeneity is observed at a frequency greater than 200 MHz for the human head, i.e. beyond a three-tesla static magnetic field.

Thanks to ASTRE funding granted by the Essonne General Council, work continued with development of an antenna (on the left in the picture) equipped with 11 linear resonators and a disk-type resonator, all used for both transmission and reception; the disk offers significantly enhanced illumination of the top of the head (picture on the right). Ten loop-shaped resonators complete this assembly to increase reception sensitivity to ensure high image resolution. Measurements taken at seven teslas on this antenna, equipped with 22 receiver coils, demonstrated greater sensitivity than an off-the-shelf antenna that was not compatible with parallel transmission but equipped with 32 receiver coils. However, it is generally accepted that sensitivity increases with this number. Our developments have therefore opened the way to other possibilities for optimizing antenna sensitivity without increasing the number of receiver coils. They also validate the patent applications filed for antenna construction and will be easy to transfer to 11.7 teslas for the ISEULT project. At the end of 2013, a joint I2BM-IRFU team was set up to sustain skills and expand them to include preclinical antennas, intended for rodents and subhuman primates, in particular those used in multi-nuclei modes for functional MRI.

• Innovation for detection systems › Achievements in response to societal challenges