The high luminosity phase of the LHC (HL-LHC) should enable the collection of a dataset unprecedented in the history of particle physics. In order to record these data, the Atlas detector will undergo a major upgrade. IRFU, via the Paris-Cluster in synergy with two other laboratories in Ile de France, is committed to the construction of a part of the internal tracker. The year 2021 is brilliantly starting for the Paris-Cluster, which has just passed an important milestone in this endeavour: the first phase of the assembly and testing processes developed by our teams has been validated by the Atlas collaboration.

The high luminosity version of the LHC

As the LHC prepares to restart for a new data acquisition from 2022 to 2025, its teams are already preparing the next stage: the High Luminosity LHC, known as HL-LHC, a phase that will begin in 2027. The HL-LHC will allow the accumulation of an unprecedented amount of data (20 times more than the current amount) in order to unlock, among other things, the secrets of the cornerstone of the standard model of particle physics: the Higgs boson. The study of its properties could reveal traces of new physics, beyond the standard model. Nevertheless, in view of the extreme conditions anticipated with such luminosity, the detectors must undergo a significant upgrade. The installation of this new equipment, accelerator and detectors combined, will take place during the third technical shutdown of the LHC, between 2025 and 2027. During the HL-LHC phase, the conditions in terms of particle density and radiation will be such that parts of the existing detectors must be completely replaced. In particular, the ATLAS internal trace detector, which detects the passage of charged particles as close as possible to the collision point, will have to be completely changed. This new detector, called ITk, will be composed of silicon modules and will cover 7 times more surface area than the current detector with a number of electronic channels two orders of magnitude larger. It will be built by a collaboration of more than 100 institutes including the Paris-Cluster, comprising about twenty people from the different laboratories of IRFU (Saclay), IN2P3/LPHNE (Paris) and IN2P3/IJCLAB (Orsay).

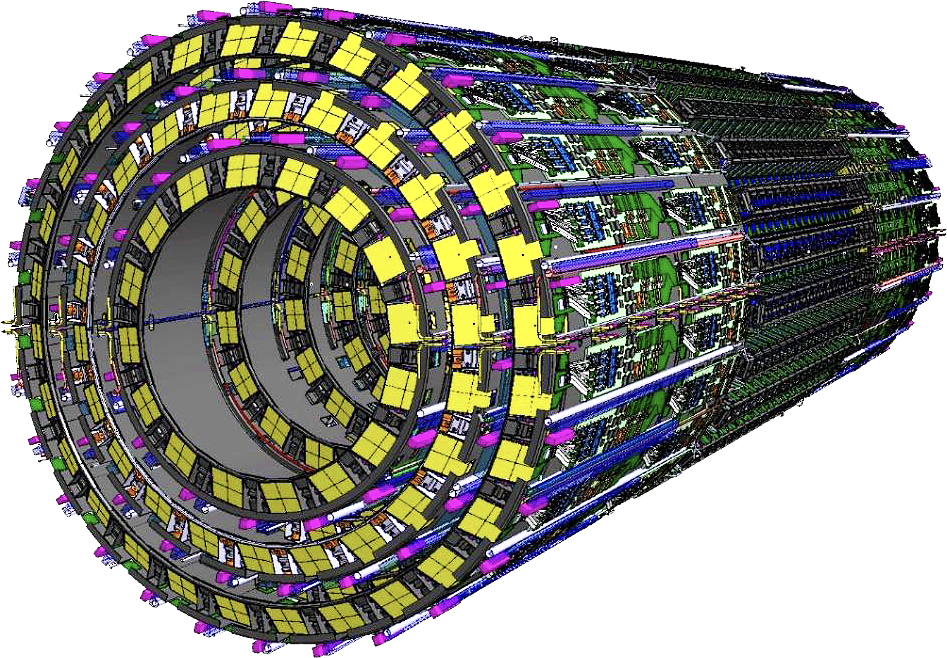

3D view of the ITk-pixel outer barrel showing the 3 layers totalling 6800 modules. (credits: ATLAS collaboration/CERN)

A new tracker for the Atlas detector

The ITk detector consists of a very high granularity part located near the beam called ITk-pixel and a part called ITk-strip with a larger radius which is less segmented. These two parts are both made up of 5 layers of silicon detectors and will operate at -30°C. The Paris Cluster has undertaken to build one third of the modules in layers 3, 4 and 5 of the central part of the ITk-pixel, called the ITk-pixel outer barrel. After validation of this construction by the ATLAS collaboration, the Paris-Cluster will be responsible for the assembly of approximately 2250 of the 6800 modules that make up this part of the ITk.

The Paris-Cluster is involved in the construction of the tracker

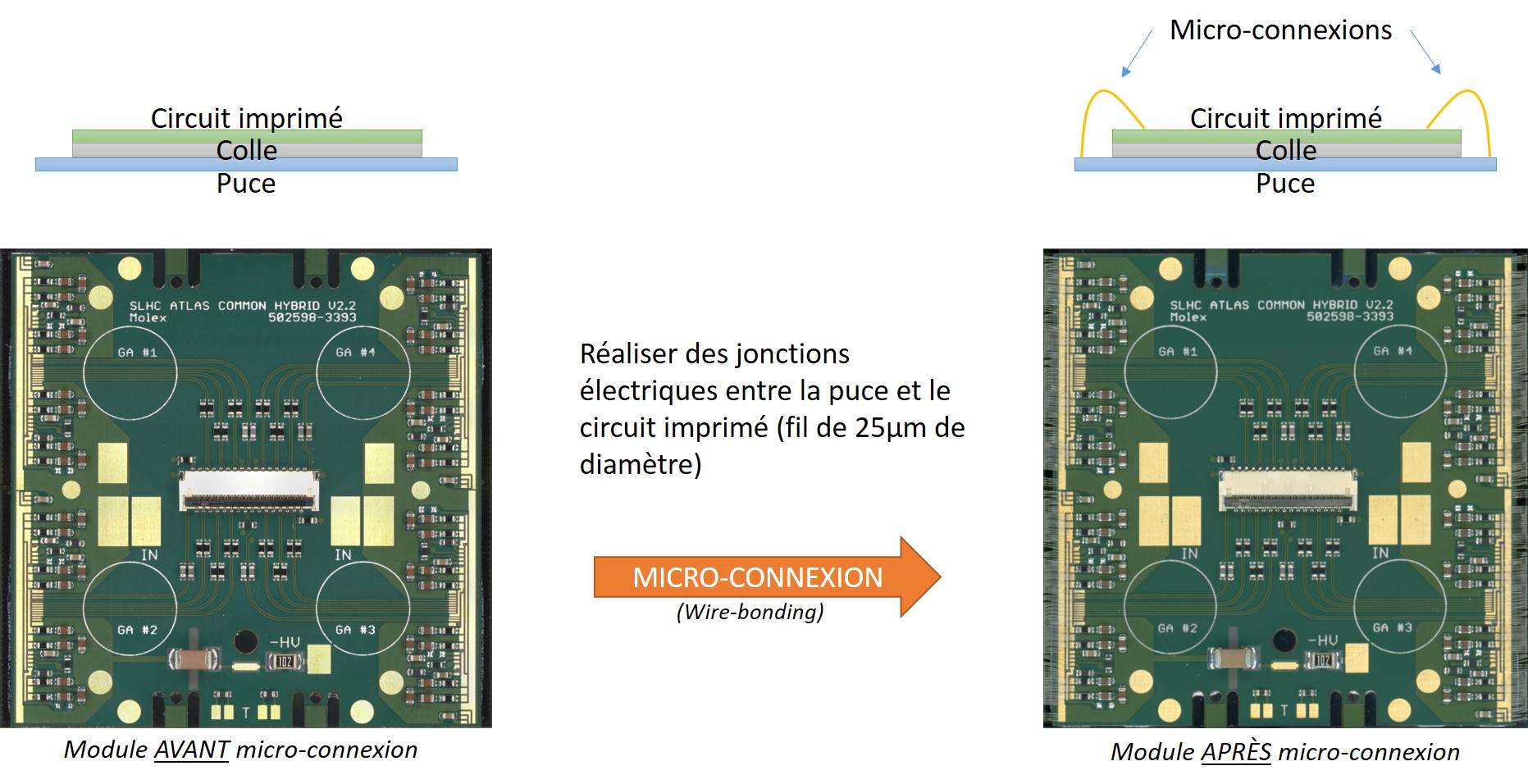

First, the printed circuit is glued to the chip (sensor) and

then the micro-connections between the two are established. (credit: CEA/IRFU)

Principle of chip assembly as carried out by the Paris-Cluster. First, the printed circuit is glued to the chip (sensor) and then the micro-connections between the two are established. (credit: CEA/IRFU)The components of each module will be delivered to the Paris-Cluster for assembly and testing. The first task of the Paris-Cluster will be to carry out the metrology of the chips and printed circuits received, in order to check that the dimensional specifications are respected. After a cleaning phase, these components will be glued together. Then the micro-connections between the chip and the printed circuit board ("wire bonding") will be made using 25 μm diameter aluminium wire. After power and communication tests at room temperature, the micro-connections will be coated with a protective layer. Finally, tests will be carried out between -55°C and +60°C during thermal cycles to verify the robustness of the modules.

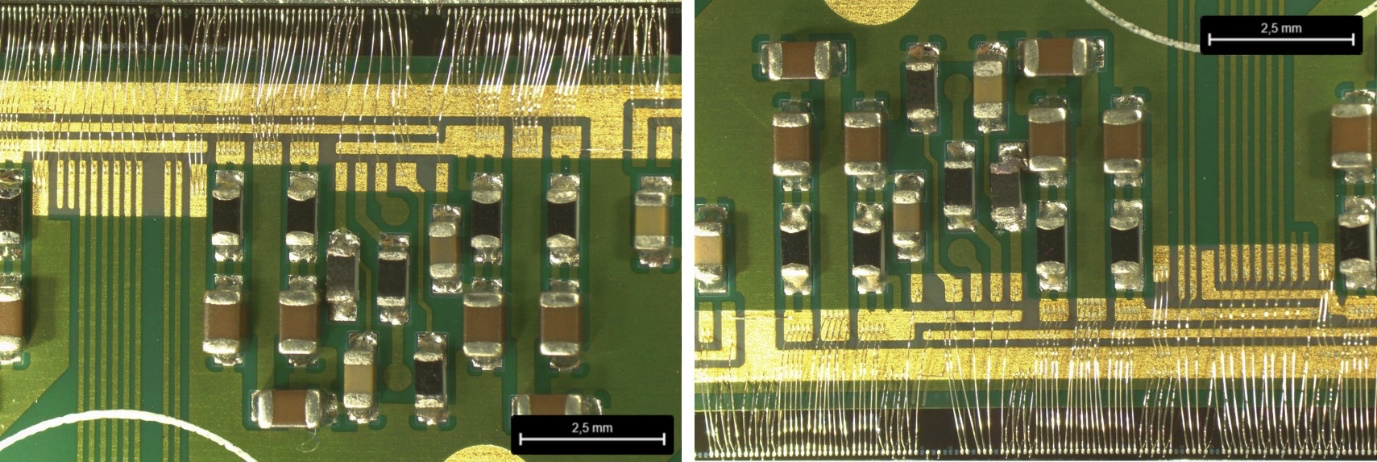

Making the micro-connections between the chip and the printed circuit (wire bonding). (credit : CEA/Irfu)

Qualification!

In order to obtain qualification for the assembly, 5 modules, with non-functional chips, must be completed in a row in compliance with the specifications. In order to make rapid progress towards this goal, the Paris-Cluster has organised itself by dividing up the tasks: the LPNHE is responsible for metrology, the IJCLAB for bonding the chips and the IRFU for the micro-connections between the chip and the printed circuit. This subdivision may evolve in the future to allow for redundancy between the three laboratories, which is necessary in the event of a device failure.

To carry out the assembly stage, Irfu has acquired specific equipment, in particular an automatic machine for wire bonding, a high-resolution scanner and a stereo microscope with integrated camera for visual inspection of the modules.

During the qualification period (September to December 2020), micro-connections were made on 20 ITk modules. This represents a total of approximately 24000 welds, 24 m of 25 μm wire used. Thanks to these achievements, on 8 December 2020, the Paris-Cluster was qualified for the first phase of module assembly.

Preparing for the final...

The second phase of qualification is now beginning. Over the next few months, the Paris-Cluster will be building and testing modules with functional chips: from acceptance of individual elements received to cold characterisation of the modules.

At the end of these qualification phases, the laboratories will set up the pre-production of prototype modules. Production of the final modules should begin at the end of 2022.

Contact: Julien Giraud

• Innovation for detection systems The ultimate constituents of matter

• The Electronics, Detectors and Computing Division • The Particle Physics Division

• Laboratory of Mechanical Studies and Detectors Integration (LEMID) • ATLAS

• ATLAS