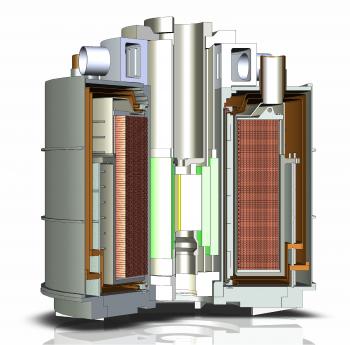

Cross-section of the hybrid magnet for the LNCMI. In green: the resistive magnets. In brown: the superconducting magnet that will be arranged in double pancake coils.

The National High Magnetic Fields Laboratory (LNCMI) in Grenoble is building a hybrid magnet capable of generating 43 teslas in a diameter of 34 mm by combining resistive magnets and a superconducting magnet. In the end of 2010, following preliminary feasibility studies, the CNRS and CEA signed a collaboration agreement putting SACM in charge of design studies and monitoring of construction of the 8.5-Tesla superconducting electromagnet. The hybrid magnet will comprise a concentric assembly of resistive magnets that will generate 34.5 teslas (Bitter coils and polyhelix coils) in the center of the superconducting solenoid to be created.

The solenoid superconducting magnet is designed with a superfluid helium channel inside its conductor, to prevent transition when there is a variation in the central field of 1 Tesla per second, corresponding to the increase and decrease of the current in the resistive magnets. This solenoid, having an internal diameter of one meter, shall be able to withstand very high levels of mechanical and electrical stress in the event that the magnetic field of the central resistive magnets is accidentally lost. In this case, the magnet will be temporarily be subject to a mechanical pulse equal to 3 times its mass (75 tonnes) and the eddy current screen will be supporting 100 times its mass (370 tonnes). These mechanical stresses and the voltages caused by the eddy currents will make it impossible to prevent the superconductor's transition in the unlikely event of this extreme accident situation. We have calculated the components so as to prevent a destruction of the cryostat and to mechanically reinforce the superconducting magnet.

The designs performed over the course of 2011–2012 covered the calculation of transient accident conditions, the design of the coil and the cryostat, and the design and development of cryomechanical support systems. These supports are very elaborate and robust enough to absorb temporary impacts while maintaining the permanent heat supply level (0.3 W) needed to keep the magnet at 1.8 K. A patent is currently being obtained for their design, which is highly innovative in terms of shape and quality of insulation with respect to their mechanical strength.

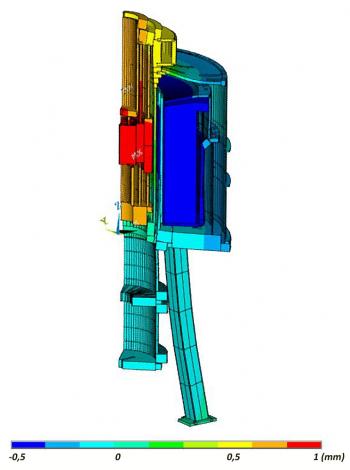

Mechanical vibration analysis of the structure of the hybrid magnet (in blue: the superconducting solenoid; in red: the resistive magnets). Vertical movements amplified by 200 at t = 7 ms after the incident. Calculations performed on a quarter of the structure using the ANSYS code based on a model initially studied by the LNCMI in 2004, then adapted and rewritten for the configuration of the current magnet by the SIS in 2012. Although the elements were all securely held in the structure, the calculations predict millimeter shifts resulting from structural deformations.

• superconducting magnet physics and technology › Superconducting Magnets for Particle Physics Research