METIS is a first-generation instrument for the ELT, the Extremely Large Telescope currently under construction in the Atacama Desert in Chile, which will see its first light in 2028. Irfu has been involved in this instrument since 2018. In 2021, 14 cryomechanisms that will drive a dozen optical systems on the METIS instrument were delivered. METIS comprises two separate units: one for spectroscopy, the other for imaging. The latter contains coronagraphs, based on phase masks. The performance of the masks designed by the University of Liège has been optimised by measurements carried out on the astrophysics department’s optical bench dedicated to infrared imaging. In April 2024, after 6 months of testing and performance optimisation, the three masks for N-band coronagraphy (7.5-13.5µm) were delivered to the METIS consortium. They will shortly be integrated into the instrument, which will enter the manufacturing phase in 2024.

Mask characterisation for coronagraphic imaging

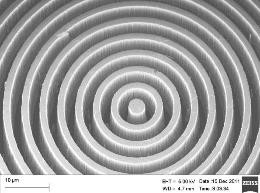

In METIS, coronagraphs are based on phase masks (Annular Groove Phase Mask or AGPM). These are synthetic diamond discs, 15 mm in diameter and 300 μm thick. Each disc is engraved with a circular micrometric grating, with a period of around 2 μm and a depth of 10 to 15 μm.

The performance of a coronagraph is measured by its rejection rate, i.e. the level of extinction of a star whose image is placed at the centre of the mask. However, it is very difficult to produce these masks with the right parameters the first time. On the other hand, it is possible to correct their shape after estimating their real shape, which is deduced from the measured performance.

The infrared bench test

The DAp infrared bench, developed between 2005 and 2007 to characterize the MIRIm instrument, the imager for JWST/MIRI, has been adapted to measure the performance of the METIS coronagraphs. It includes a room-temperature star simulator with an adjustable pupil, as well as an extended source, a monochromator, and a PLC-controlled cryostat in which the instrument is placed.

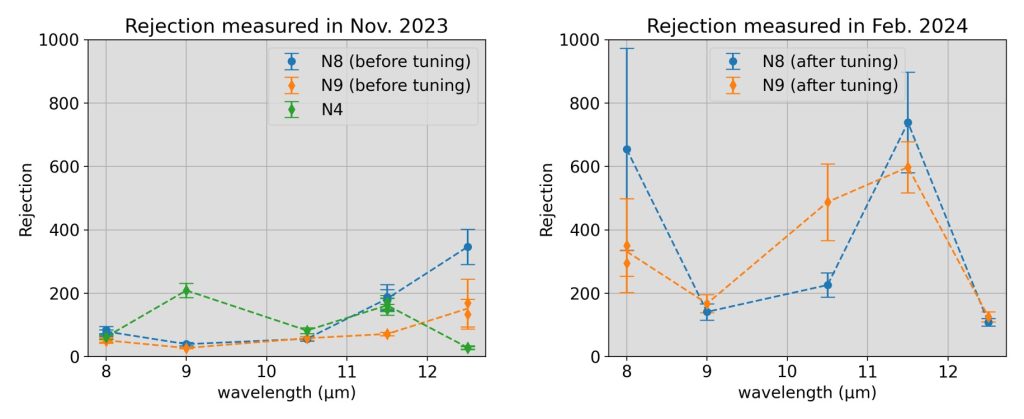

Measurements at 5 different wavelengths were needed to trace the grating shape of the AGPM mask. The bench was therefore equipped with five QCL (Quantum Cascade Laser) lasers at 8.0, 9.0, 10.5, 11.5 and 12.5 μm.

Measurement method

A series of measurement campaigns were used to test the AGPM mounting, characterise the bench’s performance and establish the best method for making accurate and repeatable photometric measurements.

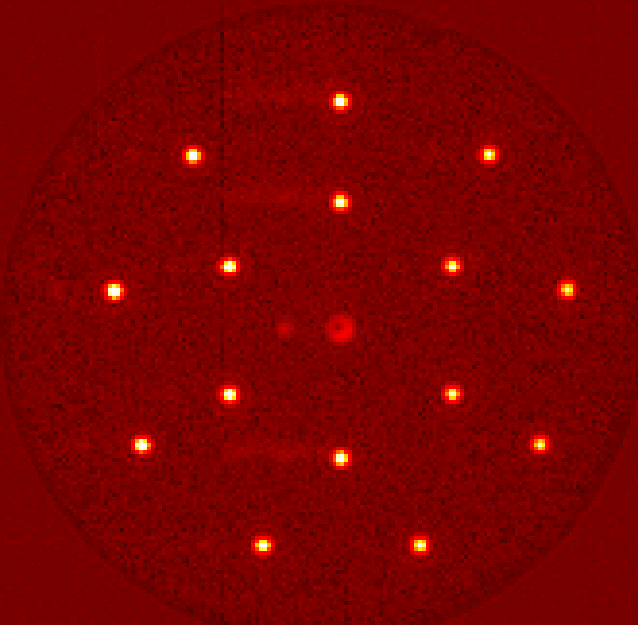

The basic principle is to measure the flux of the artificial star once outside the mask, at several positions, and then a second time centred on the mask (see figure opposite). The ratio of the two fluxes gives the rejection rate of the mask. This measurement must be repeated at all wavelengths and for all masks.

By carrying out hundreds or even thousands of acquisitions as close as possible to the estimated centre of the mask, we necessarily end up with an image for which the extinction of the source is almost optimal.

Three AGPM N-band masks, named N4, N8 and N9 were received in autumn 2023. To meet the needs of METIS, it is specified that the coronagraphs must have a rejection ratio greater than 100 on average over the entire spectral band 8-13 μm, and greater than 20 at each wavelength. A measurement campaign carried out in November 2023 showed that one mask met these specifications, and that the other two had rejection rates that were too low at short wavelengths. The tests showed that the depth of the engravings had to be reduced by 800 nm. This correction was made in January 2024 and a new measurement campaign followed in February 2024. With the masks optimised in this way, we obtained much higher rejection rates, improved by a factor of 3 to 7 depending on the wavelength.

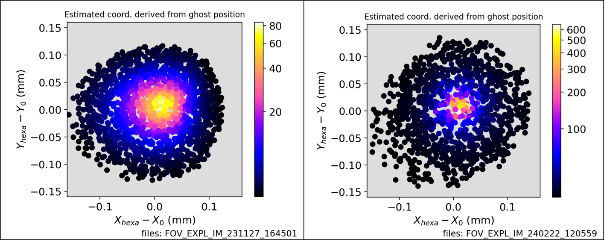

From the scans, we can draw a map of the rejection rate, to see its profile in 2D, as a function of the distance from the centre. We can see that following corrective action on the engraving, the rejection rate maps are much sharper, showing that the coronagraph is performing better: the central source is more attenuated, and we can observe a secondary source, an exoplanet, even closer to the central source.

Conclusion

Following the measurements, the masks were delivered to the University of Liège, marking the end of the team’s work on the METIS AGPM masks. Researchers from the DAp’s Spatial Systems and Architectures Laboratory have shown that optical measurements are relevant for tracing the shape parameters of the AGPM grating. In addition, the corrective action on the etching is very well mastered by the laboratory at Uppsala University. In the end, three masks meeting the specifications were delivered, and two of them performed particularly well.

Contact: Samuel RONAYETTE