On October 28, 2014, CEA signed a contract with the Israeli research center in Soreq (SNRC) for the construction of a accelerator called SARAF (SOREQ Applied Research Accelerator Facility) by IRFU teams. This agreement is materialized by preliminary and detailed study phases over a period of 18 months (2015 and 2016) opening up to a construction, testing and installation phase on the site that will last 6 years.

The aim is to build a superconducting linear accelerator capable of providing proton and deuteron beams of variable energy between 5 and 40 MeV with an intensity of up to 5mA. This facility is intended for fundamental and applied research in many fields.

The schedule, associated with this project, includes successively the delivery and installation on site and then the testing of three sub-assemblies:

- The medium energy line, MEBT (in 2020),

- The first cryomodule (in 2021),

- The three remaining cryomodules (in 2022

A time-lapse retracing the assembly and testing steps of the MEBT in the METS from November 2019 to August 2020.

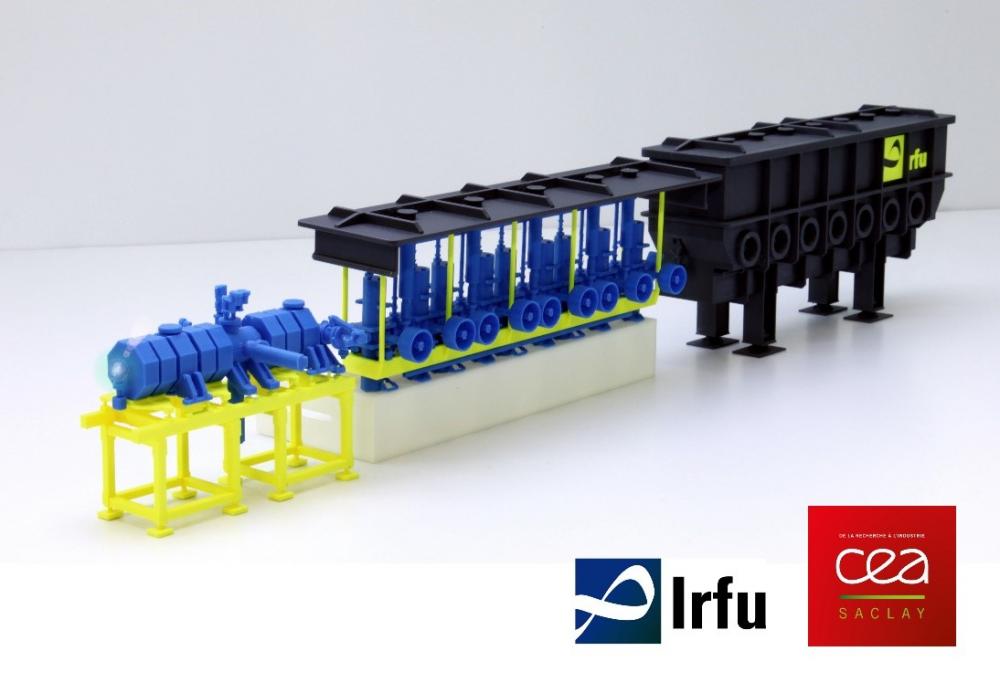

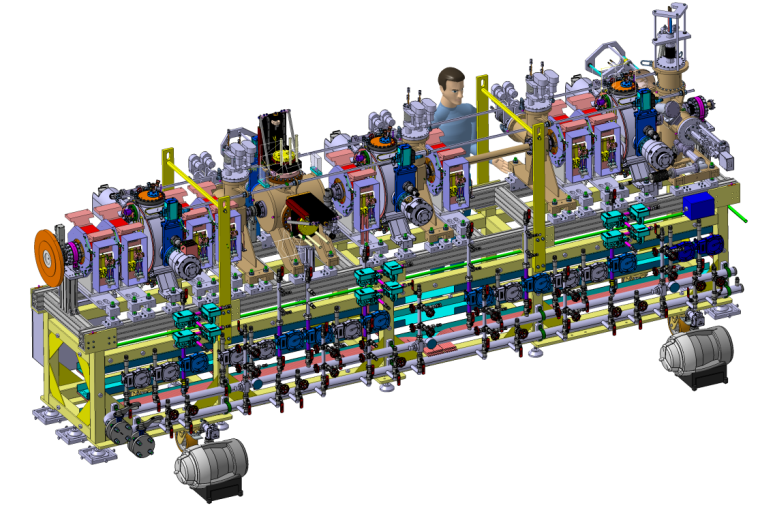

3D view of the SARAF MEBT, the connection to the Soreq RFQ is on the left and the superconducting cryomodules will connect on the right.

The MEBT

Situated between the existing RFQ and future cryomodules, the roles of the MEBT (Medium Energy Beam Transport) are extremely varied, which explains the diversity of the equipment that makes it up. Thus it must be able to:

- Guide and adapt the beam coming from the RFQ to the superconducting accelerative structures,

- Measure beam characteristics: current, position, phase, energy, transverse and temporal profiles, emittances,

- Clean the beam if necessary: adjustable slits, bunch selector,

- Minimize the residual gas flow to the superconducting part.

It therefore welcomes in particular:

- 3 RF cavities, bunching the beam,

- 8 magnetic quadrupoles, guiding and focusing the beam,

- 4 BPMs (Beam Position Monitor), measuring the position and phase of the beam,

- 2 diagnostic boxes, containing beam profile and emittance measurement diagnostics,

- 3 boxes for cleaning slits,

- A vacuum system including 5 turbo molecular pumps and 2 primary pumps, 4 valves on the beam axis,

- Water, nitrogen and compressed air distribution systems,

- Control cabinets for all the elements of the line.

The assembly is 5 meters long and weighs about 3.5 tons.

Integration & testing

From the beginning of the line design, we decided to carry out the integration in Saclay as well as a partial test of the vacuum, cooling, mechanical positioning and control (on the METS: MEBT Test Stand). The objective was to reduce as much as possible the hazards in Soreq and to limit the interventions on site by transporting the already assembled line. This choice imposed from the design stage a mechanical design capable of withstanding such transport.

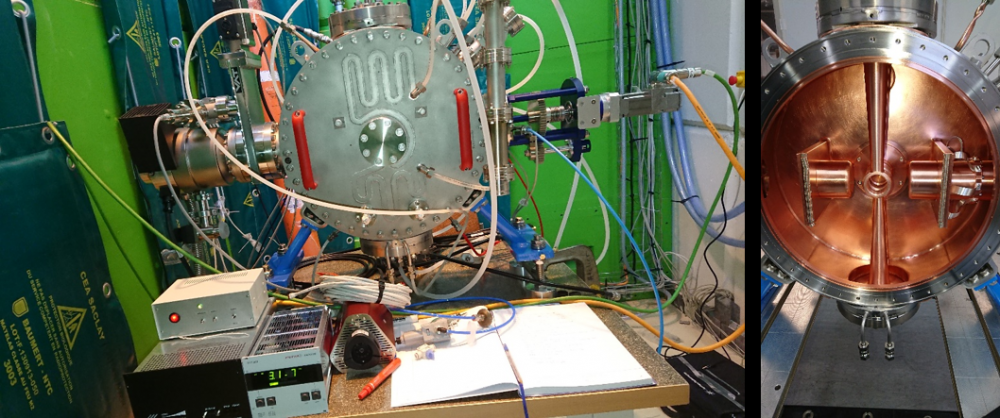

It should also be noted that the RF cavities of the rebuncher type, the result of a Ganil design, were the subject of particular attention. Thus, a dedicated test bench, the RBTS (Rebuncher Test Stand), allowed RF power testing of the 3 cavities before their final integration on the MEBT.

One of the rebuncher undergoing RF testing in the RBTS, on the left the same open cavity showing the copper coating inside the cavity.

Thus during a very short period, from November 2019 to August 2020, including a moment of lock down, within the METS, IRFU's teams performed outstanding feats, carrying out all the mechanical integration of the various MEBT components, alignment, cabling between the empty cabinet and the line components, pumping, testing the quadrupole power cabinet and the vacuum system including the main automatic procedures, as well as lifting and rolling tests. All of these operations allowed the successful validation of the design of the MEBT in Saclay.

Packed in the last week of July and delivered in the first week of August, the MEBT is now installed at its final position in Soreq and is to be progressively commissioned with the assistance of the remote IRFU teams for the time being.

The adventure continues

An important milestone in the progress of the SARAF project has been successfully achieved, demonstrating the proper design and operation of this equipment. It is the fruit of a team of more than forty people from DACM, DIS, GANIL who worked for 5 years to be able to deliver this equipment with only a few months delay on the initial schedule.

However, the adventure is obviously not over and the next steps that lie ahead, such as beam commissionning, will be crucial and exciting for the rest of the project.

Contacts: Didier Uriot, Didier Chirpaz-Cerbat

• Accelerator physics and technology Technological platforms

• Accelerators, Cryogenics and Magnetism Division (DACM) • Institute of Research into the Fundamental Laws of the Universe • The Systems Engineering Division

• LEDA