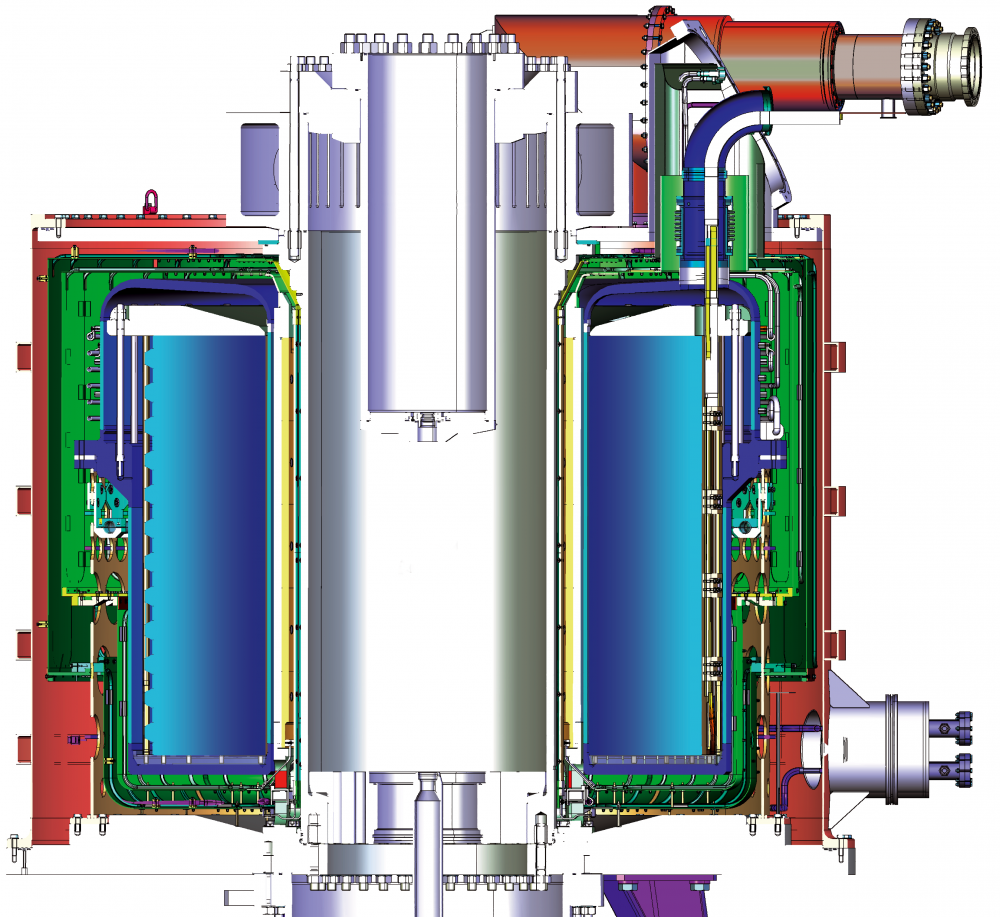

Cross section of the LNCMI superconducting electromagnet, in shades of blue, with the cryostat installed and firmly secured to the base plate to contain the forces in the event of accidental magnetic imbalance.

The hybrid magnet of the French National High Magnetic Field Laboratory (LNCMI) in Grenoble combines the 8.5-tesla superconducting coil studied at IRFU, and resistive coils studied and built by CNRS. Under the LNCMI-IRFU collaboration agreement, SACM carried out all the magnetic, mechanical and cryogenic studies for the construction of the superconducting magnet.

The hybrid magnet will generate a 43-tesla continuous magnetic field in a 34 mm diameter. The manufacturing process began at the end of 2015 and will continue over the next three years.

The coil will consist in 37 vertically stacked double pancakes connected in series to form a solenoid. The niobium titanium superconducting cable, made up of 19 strands, will be placed in a hollow copper section to ensure the energy stability of the magnet via the superfluid helium in a channel, as well as provide a rigid mechanical structure and the necessary cross-sectional area to protect the magnet from voltage rise in the event of resistive transition. A massive shield cooled to 30 K attenuates the effects of eddy currents generated by the resistive magnets on the superconducting magnet during the rise or fall phases of the magnetic field.

Energy levels and the considerable forces that could be generated in the extreme accidental case (magnetic imbalance created by the loss of the upper or lower half of the resistive magnets) called for significant additional studies to guarantee the necessary level of safety. The superconducting magnet must be able to withstand very high levels of mechanical and electrical stress should some of the central resistive magnets be lost. It is engineered and designed to withstand vertical shocks greater than four times the weight of the cold mass (100 tonnes) and four to five times higher still for the eddy current screen and the bore tube. The extension of the innovative concept originally developed for MIRI and the development of cryomechanical supports have been patented. The cryomechanical and thermal-hydraulic design of facility components ensures compliance with safety standards and ensures effective removal of the superfluid helium, pressurized at 1.8 K to 1,200 hPa, in the event of an accident. SIS also studied the magnet protection electronics and supervised component manufacture. After three years of studies, the operating and design principles have now been validated in collaboration with an expert committee and the construction phase has now started. The superconducting cable has already been manufactured. It will be inserted into its copper stabilizer at LNCMI in 2016 to form the conductor required for winding the 37 double pancake coils. Work related to the coil winding tools will begin at the contractor’s. Meanwhile, SACM and SIS are completing preparation of the technical documents for the call for tender for the cryostat, the fluid and current technical transfer line, and the remote satellite which will complete the facility.

• superconducting magnet physics and technology › Superconducting Magnets for Particle Physics Research