The instrumental electronics laboratory is in charge of developing electronic systems to measure, control or secure equipment for research in physics.

LEI is structured to respond to the different stages of an electronic project, within the framework of international research work:

Main activities :

Magnet Safety System (MSS)

LEI is a laboratory specialized in the design of MSS for the protection of superconducting magnets.

Here is a brief history of the most recent designs:

Today, the developments of the latest generation MSS are characterized by specifications whose requirements are increasing. The MSS for the ISEULT medical MRI magnet requires 4 kV insulation and a high level of reliability to ensure operational safety. The MSS for the JT60SA test station is also isolated at several kV, and is a generic system that can be used for different types of magnets, such as the LNCMI high field magnet. It integrates the Muscade remote supervision tools also deployed on the installations.

Tomorrow, the MSS will be digital and will integrate FPGA-based equipment. For example, future projects such as the STAARQ test station or the MadMax magnet will use:

Spiral 2 LLRF

LEI carried out the Low level RF (LLRF) of the 33 cavities of Linac Spiral 2 located in Ganil in Caen. The machine frequency is 88.0525 MHz. The main objective is to regulate the amplitude and phase of accelerator fields in cavities with an accuracy of ± 1% and ± 0.5°.

For each cavity, the core of the system is based on two VME64x format cards:

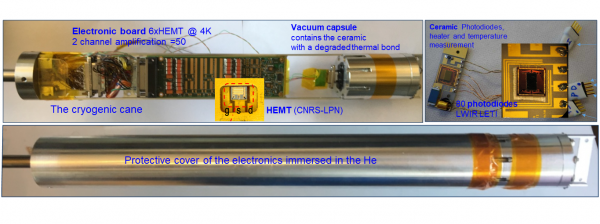

ESA-LWIR & ESA-ALFA project - Design of a cold preamplifier operating at 4K for reading calibrated photodiodes.

Cold Electronics

In collaboration with DEDIP and DAP, DIS studies and manufactures cooled amplification chains based on HEMT transistors (CNRS - LPN), for reading photodiode, Ge detectors or applications requiring very low noise measurement at very low temperatures (~1K).