« Irfu's mechanical and thermal design office »

The Design, studies and preliminary projects laboratory (LCAP) is the "mechanical and thermal design office" in charge of the architecture and design of instruments, at the service of Irfu's projects.

The LCAP brings together a group of some forty designers within a single platform. Our laboratory is involved throughout the life cycle of projects, from the upstream phase to the deployment of equipment.

Our know-how is divided into thematic areas: detection systems, space instruments, telescopes, space optics benches, particle accelerators, superconducting magnets, cryogenic systems.

The team is composed of about ten draughtsmen-projectors, about twenty permanent mechanical engineers and about ten temporary collaborators, students and post-doctoral fellows. We are involved in specification, computer-aided design (CAD), dimensioning, digital simulation and deployment assistance. We establish the definition files of the instruments which are transmitted to the industry for manufacturing via the Industry Liaison Laboratory (LRI).

The LCAP relies on the latest generation of CAD licences and an integrated database to ensure control of the digital chain and interaction with the project teams (currently being deployed). On the computing side, a wide range of tools is available to our engineers: servers dedicated to high performance computing (HPC), commercial licences (ANSYS and NX NASTRAN), access to CEA codes (Cast3m, SALOME, Europlexus, Trio-CFD, AMITEX, etc.) and other specific business tools.

The LCAP has rapid rapid prototyping capabilities.

We are pursuing internal technology watch and R&D programmes to develop our design tools to meet the physics needs of tomorrow. These substantive activities fall under three headings :

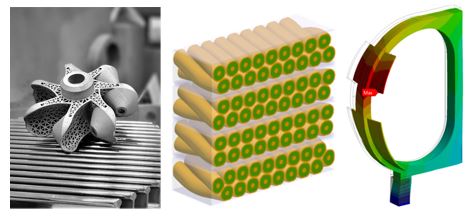

(1) Structural optimisation: optimised robot wheel produced by metal additive manufacturing (CoSTARD program, Irfu/IRFM/DES-DPC collaboration)

(2) Multiscale calculation: geometric modelling of a stack of superconducting cables (CoCaSCOPE program, DIS/DACM/CERN/CentraleSupélec collaboration)

(3) Multi-physics simulation: thermal/thermohydraulic model of a toroidal magnet of the future DEMO tokamak (dimension ~10 m) (EuroFusion/IRFM/Irfu collaboration)

The LCAP is a dynamic laboratory with recognised expertise and a long-term vision thanks to its R&D areas. The regular recruitment of permanent staff, often from the internal pool, allows the perpetuation of skills in each of the thematic areas, to ensure the best service for Irfu projects.

Nature of the LCAP's contributions by thematic axis :

Particle accelerators: In conjunction with the DACM, which carries out the electromagnetic dimensioning and beam dynamics calculations, the LCAP is involved in the design of accelerator systems: components, integrated beam lines and assembly, qualification and test tools. With a wealth of experience acquired over the course of projects (SPIRAL2, IPHI, IFMIF, FAIR, ESS, SARAF, etc.), the LCAP is responsible for the thermomechanical dimensioning and mechanical design of superconducting cavities (single or multi-cell), frequency tuning systems, cryomodules and their fittings (support structures, magnetic and thermal shielding, utilities), as well as the associated tooling. Thermomechanical calculations can be coupled with electromagnetic models. LCAP also provides expertise in the field of safety through its knowledge of the Pressure Equipment Directive and other standards.

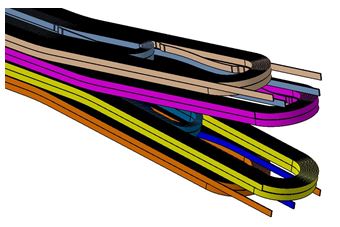

Preliminary CAD design of a prototype Nb3Sn superconducting magnet for the Future Circular Collider (detail) (DACM/DIS/CERN collaboration)

Superconducting magnets: Based on electromagnetic parameters, LCAP contributes to the design of high field superconducting magnets, from coupled magneto-mechanical simulation to the detailed definition of manufacturing, handling and transport tooling. These tools are particularly critical in the case of very high field magnets whose complex manufacturing process is carried out in-house. We have thus contributed, from a mechanical point of view, to international results in the field of magnetic resonance imaging (ISEUT, the most powerful "whole body" MRI in the world), accelerator magnets (FRESCA2 large aperture Nb3Sn dipole prototype) and high-temperature critical prototypes. The LCAP is also positioning itself at a very early stage to better understand the influence of mechanical constraints on the electromagnetic performance of the conductor. The CoCaSCOPE programme has made it possible to develop a multi-scale approach to model the mechanical behaviour of these superconducting composites, and thus to improve the design criteria. This long-term vision also covers the system approach with the implementation of multi-physics platforms that allow the coupling of software from different fields (mechanics, thermics, fluidics, magnetism, etc.), with the first framework being that of fusion magnets by magnetic confinement. Involvement in the DEMO fusion project through the Eurofusion programme has enabled us to create strong links with our partners at international level.

Detectors: this thematic area often requires a compromise between rigidity and lightness (and therefore transparency) in order to guarantee high positioning accuracy without the detector structure or services obscuring the particles of interest. Detailed predictive simulations are required, often involving complex structures with composite materials (see for example the 'little wheels' of the ATLAS detector, with a diameter of 10 metres!). Ultimately, structural optimisation offers a way to design these components.

Space instruments and telescopes: the working methodology for designing on-board equipment follows specific procedures on dedicated tools. In close collaboration with the DAp teams, the LCAP mechanical designers also participate in the assembly and specific vibration and thermal tests, which allow the digital models to be readjusted and the design to be validated. We also have expertise in the design of optical test benches, which are often very precise devices necessary for the qualification of space detectors.