The LEAS (Laboratoire d'Etude des Aimants Supraconducteurs) at CEA Paris-Saclay has entirely manufactured a coil based on the superconductor Nb3Sn (niobium-tin), of the SMC (Short Model Coil) type. This coil is a short model intended to be assembled in a magnet structure, then to be tested at cryogenic temperature. Nb3Sn is being considered for future accelerator magnets generating magnetic fields up to 16 T (teslas), which would double the performance of the best magnets currently in use. However, this requires a great deal of technological development. This type of short coil has been developed by Cern, in collaboration with the CEA, to allow the testing of new technologies and new manufacturing processes under conditions representative of future high-field magnets. The fabrication of the SMC-CEA coil took place at LEAS from May to October 2021, then the coil was delivered to Cern to be assembled in a structure, and finally tested in a liquid and superfluid helium bath, under high current, in a dedicated station. The tests delivered encouraging results, demonstrating that LEAS is one of the few European laboratories that now has all the capabilities to manufacture Nb3Sn superconducting coils. This proof of feasibility validates the first step of the development program of high field magnets for future accelerators.

The LEAS (laboratory of the Department of Accelerators, Cryogenics and Magnetism (DACM) within Irfu), with the support of the design teams of the Department of Systems Engineering (DIS) and in collaboration with Cern, is involved in an ambitious program to develop magnets for future particle accelerators, up to a magnetic field of 16 T. These electromagnets are made with coils that use Nb3Sn. This superconducting material is twice as efficient as NbTi (niobium-titanium), which is used today for the 8 T dipoles of the LHC. However, Nb3Sn is particularly difficult to use: on the one hand, it requires many manufacturing steps, and on the other hand, it is very fragile after it has been shaped.

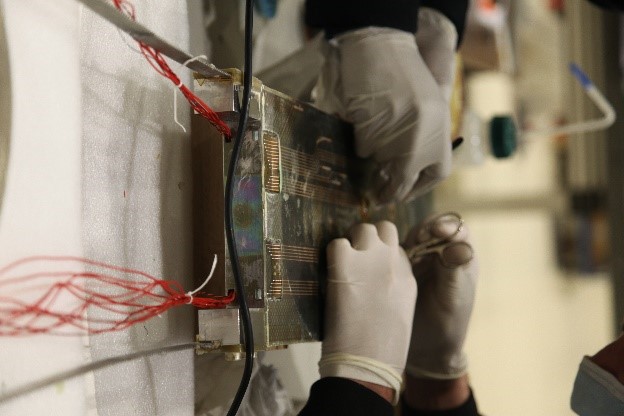

The first step in the program was to demonstrate that LEAS was capable of mastering the complex fabrication technologies related to Nb3Sn on a small 0.5 m long test coil of the SMC type. For this, Cern provided the components, its procedures, and some of the tooling. This allowed LEAS to develop its own procedures and tooling, as well as the infrastructure of its superconducting magnet fabrication facility. The SMC-CEA coil was wound in spring 2021, and finalized in fall 2021.

Then it was assembled at Cern in a mechanical structure in spring 2022, and tested in liquid helium in June 2022. The coil reached 85% of its estimated maximum current in superfluid helium at 1.9 K (kelvin), generating a peak field of 12 T. Then it reached 95% of its estimated maximum current in liquid helium at 4.2 K, with no observed degradation on the superconductor.

These results are very encouraging for the continuation of the program! The first phase, which consists of testing the manufacturing technologies and processes, is validated. The second phase is already underway: the fabrication of the R2D2 magnet, a Nb3Sn superconducting dipole entirely made at the CEA, using an innovative technology that will make it possible to reach very high magnetic fields, in very compact coils, for future accelerators.

Contact: Etienne Rochepault

• Accelerator physics and technology › R&D and Instrumentation for Future Accelerators superconducting magnet physics and technology › Instrumentation and development for R&D magnets superconducting magnet physics and technology › Superconducting Magnets for Particle Physics Research

• Accelerators, Cryogenics and Magnetism Division (DACM)

• LEAS