The PRESPEC target is intended for use in a new physics experiment requiring a thick liquid hydrogen target suited to gamma spectroscopy. It will be installed at the GSI research center in Darmstadt as part of the SPHN PRESPEC program.

SACM is responsible for the construction of this new liquid hydrogen target which has a length of 6 cm and a useful diameter of 7 cm. The hydrogen is held in a mylar tank with a wall thickness of 200 µm in order to reduce any parasitic interactions between the beam and the container. The container geometry is shaped like the finger of a glove in order to provide for analyses over large solid angles. As mylar is a thermoplastic polymer, the container geometry is formed by mechanical thermoforming at a temperature of 150°C. This technique avoids the need for any glued mylar to mylar joints, resulting in a container burst pressure of over 10 bar. The enclosure is finally glued to a moveable flange allowing the length of the target to be adjusted easily.

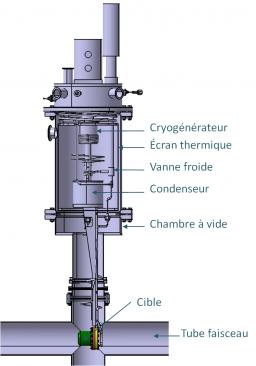

It is planned to hold the target temperature at 20.4 K with a stability approaching 0.01 K. The corresponding pressure is 101.3 kPa. The total volume of liquid hydrogen is reduced to that of the target in order to limit the quantity of hydrogen present in the installation. The gas is liquefied in a condenser mounted above the target and attached to the second stage of a cryogenerator with a cooling power of 8 W at 20 K. The target container is filled by gravity alone, and any cold vapor is collected and returned to the condenser.

Closing a cold valve on this return tube causes the liquid remaining in the target to be returned to the condenser via the feed tube. After emptying in this way, the target contains cold hydrogen vapor at 20.4 K with a density equivalent to 1.9 % of that of the liquid (70 kg/m3). In this state, it may be used to make ‘empty target’ measurements of any parasitic interactions between the beam and the container before returning instantaneously to ‘full target’ mode simply by opening the cold valve.

A control and instrumentation system has been developed by SIS to control the temperature, manage the various alarm conditions, and to return the installation to a safe state in the event of a fault.