The aim of developing ceramic electrical insulation is to study the manufacture of an insulating material that can withstand the high-temperature heat treatment (600 to 700°C) required for the formation of certain superconductors, in particular those made of niobium-tin (Nb3Sn). The conductors are wrapped with fiberglass ribbon coated with precursors which react during the heat cycle, forming the insulation and providing extra mechanical strength for the coil. Using this method, two difficult stages in the manufacture of Nb3Sn magnets are eliminated: the transfer of the very delicate reacted coil from the reaction mold to the impregnation mold, and the vacuum impregnation of the coil with epoxy resin.

Following electrical tests showing that the use of this type of insulation did not affect the superconducting properties of a Nb3Sn strand, and the good performance obtained from two small coils, this work has continued along the following lines:

- Measurements of the heat transfer performance carried out using stacks of cables which showed a significant improvement by a factor of around 100 of the extracted heat flux compared with conventional Kapton insulation.

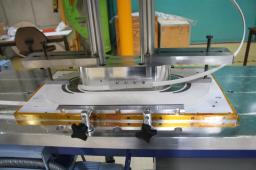

- Mechanical compression tests on stacked insulated cables. Small coils were developed for these tests.

A coil with a racetrack configuration formed from a 443 mm x 214 mm double pancake superconductor coil is currently being manufactured. This coil will be used to evaluate the insulation performance under real operating conditions. These tests will be carried out using the SMC test station at CERN.

• superconducting magnet physics and technology › Developments for instrumentation

• Accelerators, Cryogenics and Magnetism Division (DACM)

• LCSE