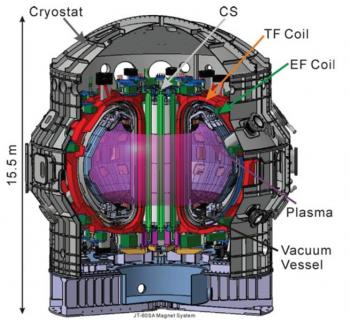

As part of the agreement between Europe (F4E, Fusion For Energy) and Japan (JAEA, Japan Atomic Energy Agency) for a broader approach to controlled fusion using magnetic containment, Europe is in charge of updating the Tokamak JT-60, located in Naka, Japan, including the design, creation and testing of 18 new superconducting toroidal magnets used for the magnetic containment of plasma. SACM is in charge of construction of the cold testing station for these 18 superconducting magnets. Testing of the first magnet is expected to take place in May 2014.

The manufacturing of 9 toroidal coils has been assigned to France's CEA; the other 9 will be manufactured by Italy's national agency for energy efficiency, ENEA. The CEA institutes involved in the testing of the coils are the Institute of Nanosciences and Cryogenics (INAC) in Grenoble, the Institute of Research on Magnetic Fusion (IRFM) in Cadarache and the Institute of Research on Fundamental Laws of the Universe (IRFU) in Saclay.

The project can be broken down into two main phases:

- the development phase consisting in the design, construction and validation of the testing station using a prototype demonstration magnet;

- the operation phase consisting in the performance of validation tests for the 18 toroidal magnets.

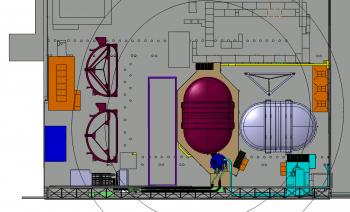

Global description of the test station. On the left: the instrumentation racks in orange, the control room in blue, electrical supply of 26,000 A in gray and the coil supports for the cryogenic tests in violet. On the right: the cryostat in violet with its valve box in blue and helium refrigerator in cyan.

The cryogenic tests of the first coils of each manufacturer (2 manufacturers of 9 coils each) will be identical to the serial tests, with the exception that they will include a quench caused by an increase in the operating temperature. These two first tests will be important for:

- checking that the two coils satisfy the technical specifications, analyzing their behavior in nominal testing conditions and controlling their temperature margin, which will define the temperature margin of the serial coils;

- controlling the proper operation of coil potential measurements and acquiring information for the operation of the future machine.

A cryostat measuring 7 m by 10 m will accommodate and test one magnet at a time. In parallel, other magnets will be prepared. The magnets will be tested at helium flowrates of 2 g/s per conductor, with an inlet pressure of 5 bar and a nominal current of 25.7 kA. The test temperature will be incremented up to the limit of quench conditions (from 5 K to 7.5 K).