Context

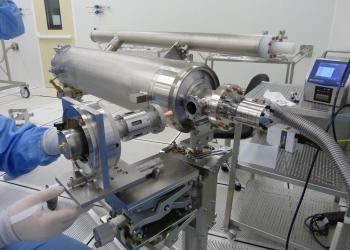

Assembly of cavities following high pressure rinsing.

Positive pressure clean room partitioned into 3 different ISO classes: 7, 5 and 4.

Technical means

- Total surface area of the clean room: a ≈ 200 m2 (of which a = 112.5 m2 at ISO class 4 with total laminar flow).

- Length of the ISO4 room: l = 15.6 m.

- Door dimensions: 2.8 m x 2.6 m.

- Ceiling height: h = 3.4 m.

- Available fluids :

- helium and argon supply network (bottle supply, P = 200 bar filtered),

- compressed air network (P = 6 bar filtered),

- ultrapure water in the 3 compartments.

- The clean room is equipped with:

- 2 changing rooms (at ISO class 5 and 7) and 1 air shower for the entrance in ISO4,

- 5 passages through bulkheads for pumping groups,

- 2 pumping groups (connection under the ISO4 technical floor),

- assembly stations (e.g. cavity-coupler),

- 108 Final Filter Units (FFU) with final filters of U16 efficiency,

- 2 railing systems located under the technical floor (distance between the rail axes : 1860 mm, length of the rails : 90 m),

- a washer BELIMED (h 1.5 m x l 1 m x w 2 m) for the external washing of cavities before their entrance in the ISO 4 clean room.

- Additional facilities :

- Air handling unit (f = 33 500 m3/h) with cooling system (P = 179 kW),

- Pure and ultrapure water treatment plant (resistivity r ≈ 17.6 MΩ, temperature T ≈ 17.0 °C),

- Control area (control of different parameters such as the rotation speed of FFU fans....).

Achievements, related projects

- Finalization of the assembly of cryomodules in the framework of the Spiral2 project,

- Assembly of 101 cryomodules (each including a string of 8 cavities at 1.3 GHz) in the framework of the XFEL project,

- Assembly of 36 cryomodules (each including a string of 4 cavities at 700 MHz) in the framework of the ESS project.

Technical steps, expertise

- Cleaning of cavities, rinsing with ultrapure water and drying (with temperature up to T = 60°C and absolute filter),

- Assembly of cavities,

- Pumping, vacuum test,

- Assembly of elements surrounding the cavity "cryostating" (insulation, magnetic shielding...) outside the clean room.

Contact: