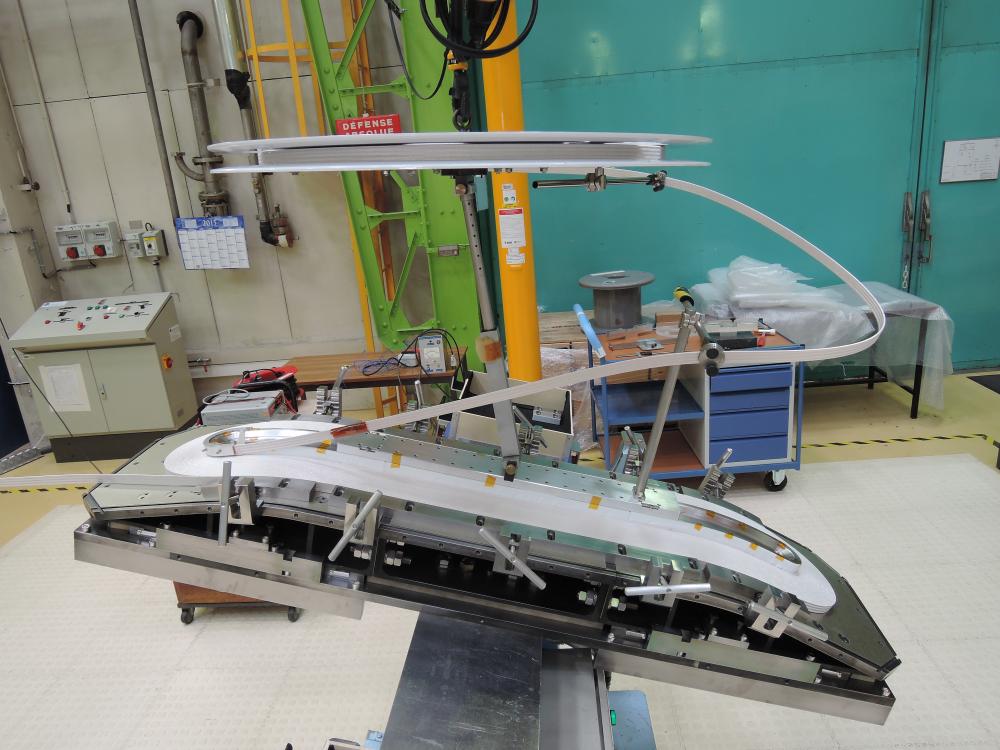

SACM’s R&D activities relating to the use of Nb3Sn as a superconducting material for high-field magnets have led to the construction of a magnet intended for FRESCA2, CERN’s new conductor testing facility. Work on this magnet is part of the European EuCARD program. The magnet, developed and constructed in collaboration with CERN, is a 1.5 m long dipole magnet that can generate a field with a strength of 13 T at the center at 4.2 K, in a 100 mm aperture, and homogeneity of around 1% over 700 mm. A block configuration was selected: each pole consists of two “racetrack” coils, with two conductor layers each, with tilted heads to allow room for the beam tube. The Rutherford conductor will be composed of forty 1 mm diameter strands.

The heat treatment (2-3 weeks at temperatures up to 650-700 °C) required to make the intermetallic compound that affords superconducting properties induces a change in cable size. The use of Nb3Sn after reaction is delicate and has technological consequences:

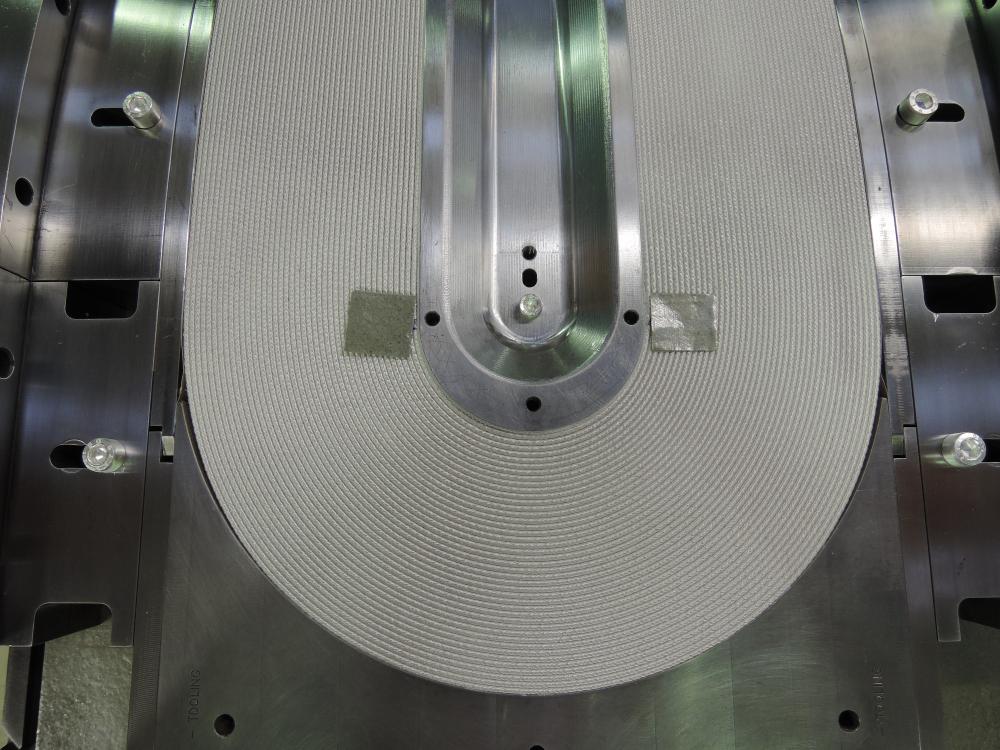

? The increase in the cross-sectional area of the conductor was taken into account right from tooling design.

? At the same time, studies were carried out to assess axial contraction in the coil.

Starting in 2013, two full-scale prototypes were made using a copper conductor to validate the various stages of production (winding, transportation, heat treatment, junctions, instrumentation, impregnation) of the double racetrack coils, and the associated tooling. The final version of the winding and reaction tooling makes it possible to open longitudinal spaces in the winding table and central island, thus allowing the tooling to follow the axial contraction of the coils. This new function was tried out during four tests performed on the superconducting cable, with the complete tooling and a reduced number of turns.

After tuning the manufacturing process, production of the superconducting coils began in June 2015, and, in spring 2016, the first four Nb3Sn double racetrack coils will be wound, reacted and impregnated. The next steps will involve assembling the dipole in its mechanical housing (which will first be tested at 77 K at CERN), then testing the dipole at 4.2 K. This is scheduled for late 2016.

• superconducting magnet physics and technology › Instrumentation and development for R&D magnets