Ten years of intense collaborative work between the DACM and DIS teams at IRFU culminated during the summer of 2024 in the successful testing of the MQYYM mock-up superconducting magnet in the new quadrupole accelerator magnet test station, STAARQ. These amazing results have validated 3 key areas of research and development that are closely interconnected between the two departments:

- Design and manufacture of a new NbTi (niobium-titanium) accelerator magnet for HL-LHC with the MQYYM magnet (DACM/LEAS and DIS/LCAP-LRI),

- Large scale cryogenics at 1.9 K with the development of the STAARQ cryogenic station (DACM/LCSE and DIS/LCAP-LRI),

- Superconducting magnet testing, with qualification of the magnet protection system based on a new digital Magnet Safety System (DIS/LEI).

This test was made possible thanks to the involvement of DIS/LDISC for the control system and DIS/LEIGE for the electrical engineering and power electronics.

The STAARQ station is ready to test the performance of new full-size magnets at 1.9 K

IRFU’s DACM and DIS teams have designed and built the new STAARQ quadrupole accelerator magnet test station at the Synergium. The cryogenic, electrical and protection systems for the superconducting magnets took 2 years to design. Another two years were required to install and/or modernise the different parts of the test station. In March 2023, the commissioning phase began, leading up to the final milestone: the demonstration and characterisation of operation at 1.9 K on a real magnet earlier this year. The next two years will be devoted to training and measurements of the magnetic performance of full-size quadrupole magnets intended for the CERN accelerator. With STAARQ, IRFU has built a test station that can achieve world-class performance and adaptability for this type of magnet test facility.

A successful test campaign at 1.9 K for the MQYYM magnet

The DACM/LEAS teams have developed and manufactured a quadrupole-type superconducting magnet made of Niobium-Titanium (NbTi), as part of the HL-LHC project to upgrade the magnets located around the interaction zones of the LHC's ATLAS and CMS detectors. The project began in 2014 with an initial design phase led by the LEAS teams (magnetic, thermomechanical, engineering, etc.). This was followed by the manufacturing of 10 NbTi coils (winding and curing) at CEA, before continuing with their instrumentation and assembly by the CEA project team at CERN.

It took the LEAS project team a year of work and travel to carry out these activities, using CERN's infrastructure and getting technical advice from CERN experts. Once assembled, the MQYYM magnet was sent back to CEA for a first successful test at 4.2 K in March 2021, followed by another test under nominal conditions at 1.9 K in June-July 2024 in the new STAARQ facility. The magnet performed extremely well, reaching a current of 6375 amperes, very close to the maximum current calculated! Numerous characterisation tests (ramp rate, temperature dependence, protection) were also carried out, demonstrating the magnet's excellent ability to respond to the various operating conditions.

Innovative deployment of a digital Magnet Safety System

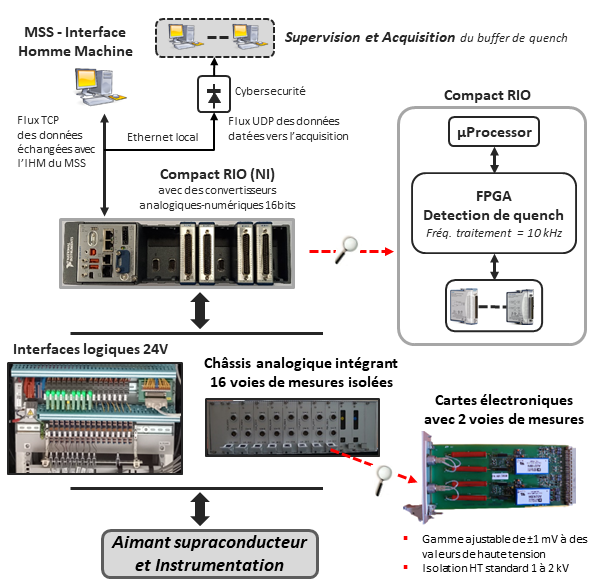

The new STAARQ station is accompanied by the deployment of a Magnet Safety System (MSS) for quench detection (i.e. the sudden transition of the magnet from the superconducting state to the resistive state) and for controlling the protection of the magnet under test. The MSS consists of a tried-and-tested analogue MSS and a new MSS where the quench detection is digital and integrated into an FPGA (Field-Programmable Gate Array, a programmable logic device). Tests on the MQYYM magnet in the early summer of 2024 fully qualified the digital MSS, detecting all 61 quenches triggered during the tests, with no false detections and improved performance compared with the analogue MSS.

• superconducting magnet physics and technology › Instrumentation and development for R&D magnets superconducting magnet physics and technology › Superconducting Magnets for Particle Physics Research Technological platforms › Development, integration and test platform for accelerators and superconducting magnets: Synergium Accelerator physics and technology

• Accelerators, Cryogenics and Magnetism Division (DACM) • The Systems Engineering Division

• LCSE • LEAS • Design, studies and preliminary projects laboratory (LCAP) • Electrical Engineering Studies and Integration Laboratory (LEIGE) • Industry Liaison Laboratory (LRI) • Instrumental electronics laboratory (LEI) • Laboratory of Development and Integration of Control System (LDISC)