A lot of equipment used in the fields of physics and health care require high magnetic fields, which are produced by superconducting magnets. This type of magnet is wound with a superconducting cable which has zero resistance at cryogenic temperature. Thanks to the property of superconduction, it is possible to supply the magnet with high currents to obtain the necessary magnetic field. If the resistance of the cable becomes non-zero, the system runs dangerously fast and causes a quench in the magnet.

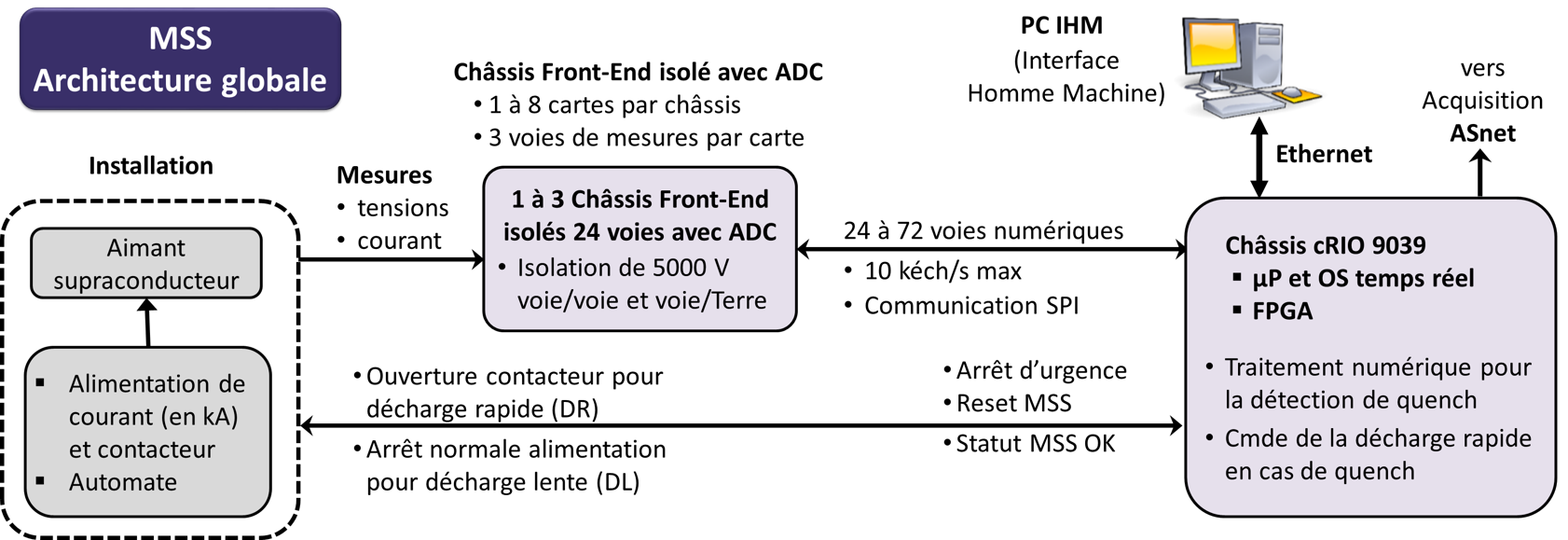

To detect the occurrence of a quench and command the magnet to be made safe, the System Engineering Departement(DIS) designs and implements Magnet Safety Systems (MSS). Their functions are to :

- Detect the occurrence of resistances in a superconducting magnet, causing a quench if the measured voltage exceeds a threshold level for a certain time T.

- Send a signal controlling the rapid electrical discharge of the magnet in case of a quench.

- Acquire measurements for off-line scientific analysis of the quench.

The quality of the measurements, which are isolated in high voltage, the reliability of the electronics and the processing of the information particular to the detection of a quench are the key elements of these systems, developed by DIS since the 1990s and before.

Historically, MSS are analogue devices. Today, the evolution of electronics and the complexity of magnets require the use of digital techniques, in order to deal with more complex detection equations or a large number of measurement channels, requiring an increased densification of the electronic equipment.

• The Systems Engineering Division

• Instrumental electronics laboratory (LEI) • Laboratory of Development and Integration of Control System (LDISC)