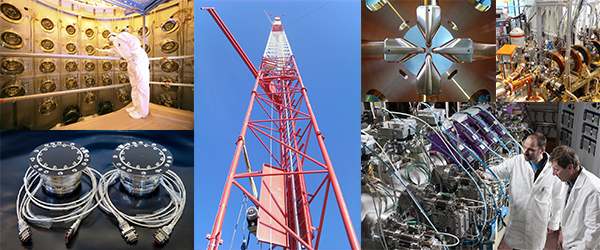

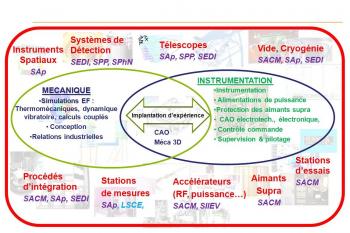

The systems engineering department is in liaison with the other Irfu departments in the fields of mechanical engineering and instrumentation, research instrument design. The DIS, because of its complementary profile, is involved from feasibility studies to the deployment of equipment and during certain projects through an industrialization phase. Working in collaboration with the other departments, DIS has led to work on diversified projects such as the development of prototype magnets for the LHC's energy rise, and the project management of a complete accelerator system for various international collaborations such as FAIR or ESS. But also the mechanical architecture and the control-command of detectors such as Clas12 and Stereo.

It contributes to the testing, maintenance and evolution of these instruments through technological infrastructures and specific equipment to carry out and characterize these achievements as cryogenic optical benches for space instruments for example.

In parallel, the department is involved in research and development activities in order to maintain their high level of competence. DIS has the capability to provide a complete cryomechanical system covering mechanical engineering, power electronics and control activities.