The JWST (James Webb Space Telescope), future successor of the HST (Hubble Space Telescope) in the year 2013, is being built by Nasa in partnership with

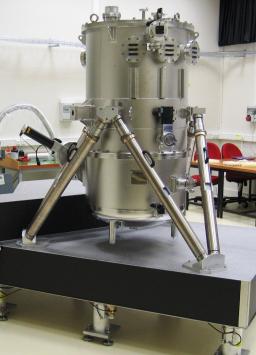

The SACM studied and established the specifications for the construction of the cryostat for the imager test bench. It is designed to cool the whole instrument, i.e. the opto-mechanical structure and the infrared detector, to a very low temperature (5 to 20 K). The temperatures will be independently controlled with a precision of +/-0.1K for the optical structure and +/-0.01 K for the detector itself in nominal conditions. Cooling and heating stages of around 10 kelvins are necessary to limit the stresses relating to shrinkage and expansion during these phases.

For reasons of stability, it was decided to use liquid helium for cooling; we use the sensible heat of the gas to maintain the desired temperature.

The Mirim assembly will be located inside a thermal shield at 4.2 K directly linked to a 100-litre liquid helium tank. A second shield at 70 K cooled by circulation of gaseous helium will reduce the radiation required for the first. This assembly is placed in a stainless steel vacuum chamber in order to hold back the heat being transmitted to it by convection and conduction in the air.

Two helium exchanger systems allow the desired temperature of the detector and the opto-mechanical structure to be controlled. The regulation of these temperatures is carried out by controlling the flow of helium in the two systems, and is adjusted more finely by small heating elements located on the heat exchangers. An automatic filling system ensures the level of liquid helium is topped up in the tank, so that the cooling is maintained throughout the test periods.